Research and development for your innovations

With the Battery Safety Campus Germany, we offer ourselves as a competent system contact for your questions regarding the safe design and operation of your mobile and stationary battery storage systems. Together with you, we drive your product development forward in joint, also publicly funded, research projects and support you with technical services tailored to your needs.

The Battery Safety Campus Germany has a unique combination of research facilities for the development and testing of innovative storage systems for mobile and stationary applications. In Goslar, renowned researchers from university and non-university research institutions as well as innovative companies from the fields of safety technology and sensor technology, among others, are working together in one place on the topic of battery safety in the area of safety, reliability, longevity and cost-effectiveness of mobile and stationary battery systems of the next generation and the generation after next in the context of an electricity-based energy system. This bundling of scientific expertise in cooperation with industry at the same location accelerates the path from the idea to market-ready products.

For stationary energy storage systems with lithium-ion batteries, which are already installed in large numbers in residential buildings, e.g. coupled with PV systems, there are hardly any adapted safety standards and guidelines in contrast to mobile applications. Technical faults in these systems, which cannot be 100% avoided, can lead to fires. Due to the associated loss of trust on the consumer side and the uninsurability of home storage systems, which is associated with high fire risks, this still young market may collapse.

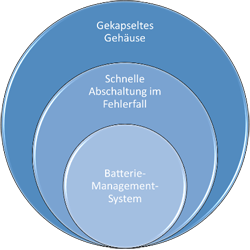

Therefore, new and suitable protection concepts must be developed and standardized for these technologies. The concept we are pursuing provides for diverse, redundant safety on three levels for all battery systems:

Level 1 - Sensors

The battery management system is used for permanent and redundant monitoring of the battery limit values. The critical operating states of all cells, such as overcharging, deep discharge, overcurrent, short circuit or temperature, are permanently monitored and avoided by means of a corresponding charge control system at cell level. Since the entire system is switched off in the event of a voltage measurement failure, a diverse redundancy of the system is required and thus monitoring of the management system at level 2.

The use of fiber optic sensors developed by Fraunhofer HHI for recording current, temperature and strain enables monitoring that goes beyond conventional measurement technology and can be integrated into standard BMS.

Level 2 - Electrics

In the event of a fault, especially short circuits, the battery system is switched off quickly and safely. Lithium-ion batteries in particular have a very low internal resistance, which leads to very high short-circuit currents in a very short time in the event of external short-circuits, with the corresponding hazard potential. The rapid disconnection of high DC charging currents required as a result is technically challenging, as the switches to be used must be able to disconnect high voltages and high currents very quickly. In addition, an all-pole disconnection of the battery is provided in the event of a short circuit. In the event of a circuit breaker failure, fuses are integrated at this level as a safety reserve. If the system is charged incorrectly, the close-meshed fiber optic measuring system with spatially and time-resolved temperature and pressure measurement values at cell level detects imminent faults at an early stage and initiates a timely shutdown of the power variables.

Level 3 - Protective cover

Finally, the batteries must be installed in fire-retardant housings whose main functions are to protect the internal lithium cells from thermal runaway and to protect them from mechanical impacts. Elements of this safety level include protection against contact/electric shock and temperature control/thermal insulation of the cells and modules. They also provide a final layer of protection to delay or contain a fire. Lining the housing components with fire-retardant materials and an adapted active extinguishing system complete the protective measures on the third level.

Battery risk management

In summary, sufficient precautions must be taken to ensure the safe installation and, in particular, the safe operation of a battery system.

In addition to the pure monitoring and observation of battery parameters, other - possibly also external - influencing variables that are necessary for the control of hazardous situations must be considered for safe operation. This can vary, for example, depending on the respective location, the application and the technical boundary conditions. Overall, appropriate battery risk management must therefore be provided for the safe operation of a battery system. If you have any questions, please do not hesitate to contact us.

The core of the equipment is the "Battery and Sensor Test Center", which covers an area of 1,500 square meters and enables, among other things, the performance of electrical, dynamic load tests up to 1000V/1200A, i.e. 1.2MW, up to the limit ranges.

Innovative fiber optic sensor systems record the physical properties of cells and battery systems as well as the spatially and time-resolved heat development or expansion in real time. Gas analysis is used for the investigation and scientific interpretation of harmful gases produced in the event of outgassing or combustion of the tested batteries. The functionality of battery systems can also be tested under controlled climatic conditions. The battery and sensor test center also has two test chambers with a downstream flue gas cleaning system in which thermal stress tests (e.g. temperature unit curve, fuel fire test) can be carried out.

This equipment is used to systematically and comprehensively record the behavior of batteries in extreme situations in order to develop and test adapted safety concepts.

Together with our partners, we also offer concepts for the professional disposal of your batteries.

TU Clausthal has published an information film about the research activities at the Battery and Sensor Test Center, which you can access here.